Plastic materials

How can we divide the plastic materials?

The material determines the mechanical properties, the look and feel (sight and touch), and the accuracy of the parts produced by additive manufacturing.

The mechanical properties of polymers such as tensile strength, stiffness, elasticity and elongation at break depend on the intermolecular forces and the hydrogen bond;

The polymeric structure can be amorphous or crystalline, and they can coexist;

Thermoplastics are usually semi crystalline (combination of crystalline and amorphous);

Thermoplastic materials with amorphous structure have elastic properties, while crystalline structures have mechanical properties;

Plastic materials are divided according to the structure , of the resulting characteristics and from heating behavior .

They can be divided into three subjects:

Thermoplastics

(low / medium stiffness, elongation and stiffness – can melt and are reusable – allow plastic deformation when heated);

Thermosetting

(greater resistance to high temperatures – more fragile than thermoplastics – they do not melt and are not reusable);

Elastomers

(high elongation – high flexibility against its breaking or cracking)

HP Materials 5200 Series

HP supplies a line of engineering-grade polyamide-based thermoplastics designed for HP Multi Jet Fusion technology.

HP 3D High Resuability PA12

Provides a strong part, achieves waterproof properties. Ideal for final parts and functional prototypes with fine detail and dimensional accuracy

HP 3D High Resuability PA11

A renewable raw material, it has higher breaking strength and impact strength and offers a good balance between performance and reliability.

HP 3D High Resuability PA12 Glass Beads

Provides consistent performance with dimensional stability, stiffness and repeatability

Basf Ultrasint ™ TPU01

A highly workable multipurpose material that offers high flexibility, shock absorption and energy return.

HP 3D High Reusability PP

Provides chemical resistance, has low moisture absorption with excellent welding ability

Nylon PA12

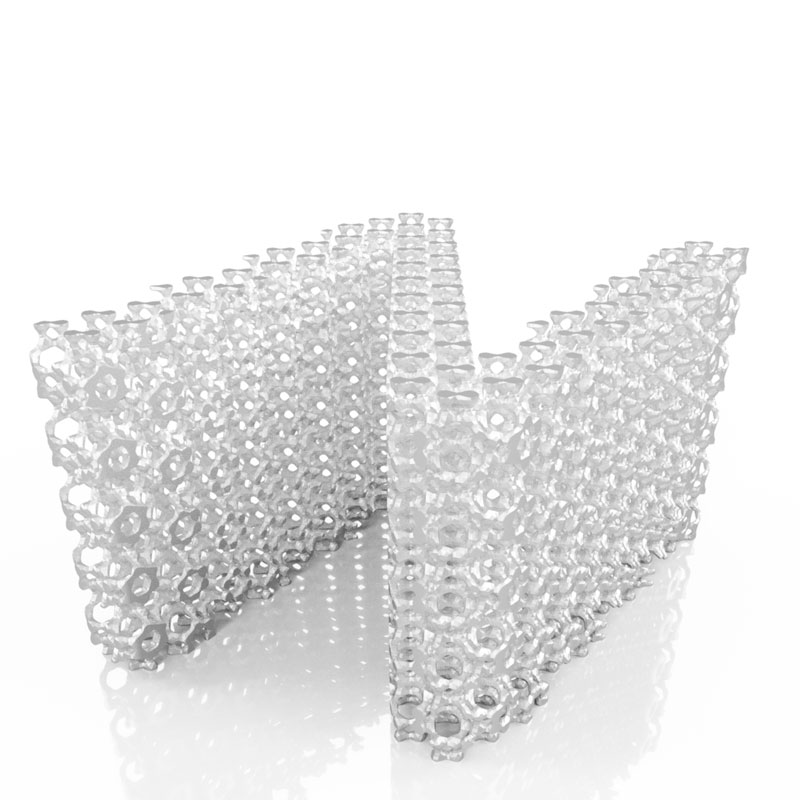

Nylon PA12 is one semi-crystalline thermoplastic material with a excellent relationship between strength characteristics is weight .

Printed in HP5210 Multi Jet Fusion is functional, has stiffness , perfect quality in detail on more complex designs and offers the better balance also in performance of the densest parts .

It is ideal for the creation of enclosures , fluid-tight elements , complex assemblies is housings , absorbing very little moisture .

This technology, for example, is also used for functional prototypes , for customized protections , for materials of gadgets , spectacle frames , molds is machinery equipment .

In the following table, we will specifically illustrate the mechanical properties values obtained by HP 3D HR PA12 in the HP jet Fusion 5200 3D printing solution with Balanced print profile and type I tensile samples, following the ASTM D638 standard.

Naylon PA 12 - I dati riportati scaturiscono da test effettuati all’interno dell’HP.

| HP 3D HR PA 12 | Asse (XY) | Asse Z | Metodo di prova |

| Resistenza alla trazione (Mpa) ⁱᵛ | 50 | 50 | ASTM D638 |

| Resistenza alla trazione (Mpa) ⁱᵛ | 1900 | 1900 | ASTM D638 |

| Allungamento allo snervamento (%) | 10 | 8 | ASTM D638 |

| Allungamento a rottura (%) | 17 | 9 | ASTM D638 |

| Resistenza all’impatto (kJ/m) | 4.2 | 3.8 | ASTM D256 |

| Densità (g/cm³) | 1.01 | 1.01 | ASTM D792 |

ⁱ. Based on internal testing and measured using HP Half_Commercial_Datasheet_Job work. The results can be from other works and geometries;

ⁱⁱ. Using HP3D HR PA12 material, 20% refresh ratio, balanced printing profile, natural cooling, and measured aer bead-blasting with glass beads at 5-6 bar;

ⁱⁱⁱ. Following all HP recommended printer setup and adjustment processes and printheads aligned using a semi-automatic procedure;

ⁱᵛ. Typical variation in tensile strength (95% of parts) is in the 45-55Mpa range, while tensile modulus values remain in the 1650-2200Mpa range;

ᵛ. Using the Izod A test method with notched specimen @ 3.2 mm according to ASTM D256;

The strength and elongation criteria are reported by the ASTM (American society for testing and materials)

Certifications HP 3D Hight Reusability PA12 material

HP 3D HR PA12

Summary of Regularity Compliance and Environmental Attributes

CERTIFICATE TECHNICAL NOTES

Add. Certiciation USP Class I-VI and US FDA guidance for Intact Skin surface devices

CERTIFICATE OF COMPOSITION

Statement of Composition for Toy Applications Certificate

Biocompatibility certificate

HP 3D600 / HP3D700 Fusing and Detailing Agents

PAHs CERTIFICATE

PAHs status of HP 3D600 / 700 Fusing and Detailing Agents

Reach / RoHS CERTIFICATE

HP Inc. Reach and RoHS status of HP 3D600 / 700 Fusing and Detailing Agent and HP 3D HR PA 12

Contact the Niuo Customer Care experts to find different solutions together and receive support.

Follow us on our social networks

Respect of the times

Once the order is confirmed, Niuo ensures delivery on time and undertakes to ensure that the deadlines are respected.

Repeatability

Thanks to the precision and accuracy of the machining it will be possible to produce repeatable pieces based on the required quantities.

Ready to get started?

Upload the file of your project to know the costs and time required for implementation.

Everything can be different. The impossible becomes possible.

The possible becomes simpler.