3D printing technology with HP Multi Jet Fusion 5210 is currently the more advantageous in terms of speed and control of the properties of the parts .

The Multi Jet Fusion (MJF) printer is a system of 3D printing in a powder bed , able to fuse the fusion and detail agents to the powder by binding them together.

It allows us to produce and create unique, more complex parts, maintaining excellent dimensional characteristics, mechanical properties and excellent surface finishes, at low costs and in a very short time.

What is the printing process and how does it work?

The HP 5210 MJF 3D Printer starts by spreading thin layers of plastic powder over the work area.

Subsequently, the carriage containing the printheads will pass over the powder bed, releasing drops of agents.

The fusion agent through the energy of the lamps, at a temperature between 182 ° and 186 °, will melt in the section of the interested parts, while the detail agent will be deposited in the contour to block the fusion and optimize accuracy of the parties.

This process continues layer by layer until a finished and functional part is formed.

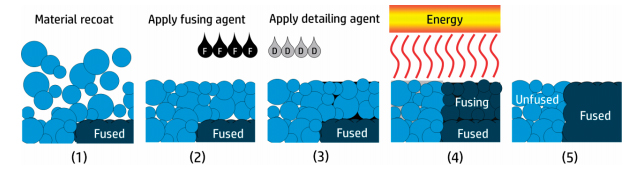

- The material is released over the entire work area.

- A fusing agent is selectively applied where the PA12 particles must fuse together.

- A detailing agent is selectively applied where the fusion action is to be reduced or amplified.

- The work area is exposed to fusion energy.

- The part now consists of fused and unfused areas.

The whole is repeated until the complete part has been formed.

What are the reasons for choosing the Multi Jet Fusion 5210

The HP MJF 5210 printer allows us to design assembled parts, to print every single piece, even small complex and thin parts, while maintaining dimensional accuracy and presenting a look and feel great .

This technology uses fine-grained materials, which is why it allows us to create ultra-thin layers (80 µ) .

The print time , if we take into consideration a whole printing unit (380 * 284 * 380mm) it can have a duration maximum of 14h .

The parties are then subjected to a process of cooling down , which allows them to maintain optimal mechanical properties over time .

Thanks to these characteristics and its innovative evolution, it has already taken up field in several sectors fundamentals that are part of our daily life ( automotive , doctor , optical , musical etc …) with excellent results.

For example this technology in the medical field recently, has been able to also fight the Covid-19 pandemic , with the design in a very short time of many applications , greatly facilitating us.